Petroleum distillate is a type of fuel derived from crude oil, which is composed of hydrocarbons and other organic compounds. This type of fuel is used in a variety of applications, including transportation, heating, and industrial processes. Petroleum distillates are produced through a process known as fractional distillation, which separates the various components of crude oil based on their boiling point. The resulting product contains various fractions with different boiling points and properties, each with its own unique uses.Petroleum distillate is a generic term for any liquid derived from the distillation of petroleum. It includes crude oil, gasoline, diesel fuel, jet fuel, kerosene, naphtha and other products derived from petroleum refining.

Types of Petroleum Distillates

Petroleum distillates are a broad category of chemicals derived from crude oil through a process known as distillation. This involves heating the crude oil to temperatures of up to 700°C and collecting the vapours, which are then condensed into a liquid form. The resulting liquid is further processed and separated into fractions, each with its own unique properties. These fractions include gasoline, diesel fuel, lubricating oils, waxes and asphalt. Each of these fractions can be further divided into different types depending on their specific properties.

Gasoline is a type of petroleum distillate that is used mainly in passenger vehicles for transportation. It is a volatile liquid consisting of hydrocarbons and aromatic compounds such as benzene, toluene and xylene. Gasoline has a high octane rating which gives it good performance when used in an engine.

Diesel fuel is another type of petroleum distillate that is produced through distillation of crude oil. Diesel fuel contains hydrocarbons with higher boiling points than gasoline, making it more suitable for use in diesel engines where higher compression ratios are needed for combustion. Diesel fuel also has lower emissions than gasoline due to its higher boiling point and lower volatility.

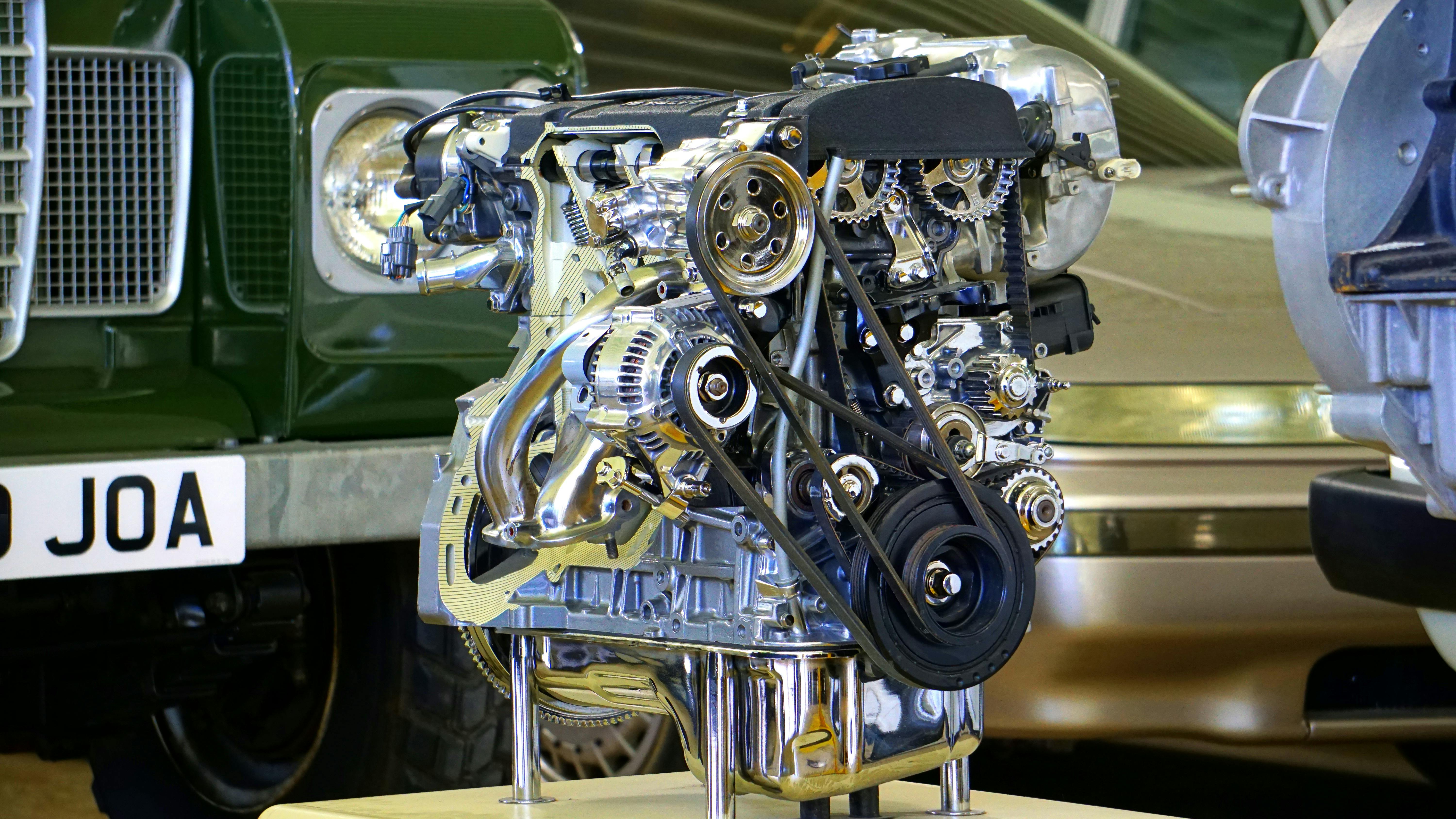

Lubricating oils are also produced from petroleum distillates, typically through fractional distillation processes such as cracking or hydrocracking. These oils are used mainly in internal combustion engines to reduce friction between moving parts, as well as providing protection against corrosion and wear. The most common types of lubricating oils include engine oils, gear oils and hydraulic oils.

Waxes are another type of petroleum distillate that can be produced through fractional distillation processes such as solvent refining or de-waxing. Waxes have many uses in industry including being used as industrial lubricants, sealants and coatings for products such as food containers or packaging materials.

Asphalt is yet another type of petroleum distillate that is produced through a process known as vacuum distillation or de-asphalting. Asphalt has many uses including being used for road paving and roofing materials due to its waterproofing properties. It can also be used in paints or other coatings due to its ability to resist corrosion and heat transfer.

In summary, there are many types of petroleum distillates that are derived from crude oil through various fractional distillation processes such as cracking or solvent refining. These include gasoline, diesel fuel, lubricating oils, waxes and asphalt which all have their own unique properties depending on their composition and production method.

Where Does Petroleum Distillate Come From?

Petroleum distillate is a by-product of the crude oil refining process. It is produced when crude oil is heated to extremely high temperatures in order to separate out different types of hydrocarbon molecules. The resulting mixture consists of a variety of different hydrocarbons, including gasoline, diesel, kerosene, and lubricating oil. This mixture is then further distilled and refined in order to produce usable products.

Petroleum distillates are used in a wide range of applications, from fuel for vehicles to lubricants for industrial machinery. They are also used as heating fuels, in the production of chemicals and plastics, and in many other industrial processes. Petroleum distillates are also used as solvents in paint strippers, cleaners, and polishes.

The refining process requires a large amount of energy and resources. Refineries use heat from burning natural gas or other fuels to heat the crude oil until it vaporizes. This vapor is then separated into its component hydrocarbons through fractional distillation. The fractional distillation process involves boiling off the lightest fractions first and collecting them separately before moving on to heavier fractions. The collected fractions are then further refined into petroleum products such as gasoline, diesel fuel, kerosene, and lubricating oils.

In addition to being produced through fractional distillation at refineries, petroleum distillates can also be manufactured synthetically from coal or natural gas liquids such as ethane or propane. Synthetically produced petroleum distillates typically have lower sulfur content than those produced through traditional refining methods.

Petroleum Distillate Refining

Petroleum distillate refining is the process of transforming crude oil into useful products. The most common products from this process are motor fuel, heating oil, and aviation fuel. Refining involves separating the various components of crude oil through a distillation process. This process typically involves heating the crude oil to high temperatures and then boiling off different fractions at different temperatures. The fractions that are distilled off are then processed further to produce different types of fuels or other useful products.

The first step in refining petroleum distillates is to separate hydrocarbons by boiling point range. This is done by heating the crude oil in a distillation tower and allowing it to boil off at different temperatures. Once the fractions have been separated, they are further processed to create specific products such as gasoline or diesel fuel. This involves cracking or breaking down larger molecules into smaller ones, blending with other substances, and other steps depending on what product needs to be created.

The resulting products are then tested and treated to meet certain specifications set by regulatory agencies or industry standards. For example, motor fuel must meet certain octane levels in order to perform properly in an engine and must also meet certain sulfur content requirements due to environmental regulations. Fuel additives may also be added during this stage in order to improve performance and reduce emissions.

Once the fuel has been tested and treated it can then be packaged for sale or distribution for use in various applications such as motor vehicles, aircraft, ships, and power plants. Petroleum distillate refining is an important part of the energy industry that helps provide us with essential fuels needed for transportation, heating, and electricity generation.

Properties of Petroleum Distillate

Petroleum distillates are a group of liquid hydrocarbons that are obtained during the refining process of crude oil. These products have a wide range of uses and are classified according to their end use. Petroleum distillates are characterized by their boiling point range and chemical composition. The following properties of petroleum distillate make them so versatile:

1) Boiling Point Range: Petroleum distillates have a wide range of boiling points, from near ambient temperature to above 500°F (260°C). This makes them suitable for use in a variety of applications, from low-temperature lubricants to high-temperature fuels.

2) Chemical Composition: Petroleum distillates contain hydrocarbons such as paraffins, naphthenes, aromatics and other compounds. The composition varies depending on the source and refining process used.

3) High Flash Point: Petroleum distillates typically have a flashpoint between 110°F (43°C) and 140°F (60°C). This makes them suitable for use as fuel or lubricants in certain applications where there is a risk of fire or explosion.

4) Low Viscosity: Petroleum distillates tend to have lower viscosity than other petroleum products, making them ideal for use in low-viscosity lubricants or fuels that require minimal friction.

5) High Heat Capacity: Petroleum distillates have a high heat capacity, which means they can absorb large amounts of heat without significant changes in temperature or boiling point. This makes them useful for applications that require thermal stability and/or heat transfer capabilities.

6) Low Sulfur Content: Many petroleum products contain high amounts of sulfur, which can be damaging to engines and other surfaces when used as a fuel or lubricant. However, petroleum distillates typically contain only trace amounts of sulfur, making them suitable for use in sensitive equipment or environments where sulfur contamination is not desirable.

How is Petroleum Distillate Used?

Petroleum distillates, also known as petroleum-based or hydrocarbon-based distillates, are derived from crude oil and are composed of aromatic hydrocarbons such as benzene, toluene, xylene, and naphthalene. Petroleum distillates are used in a variety of industries, including automotive manufacturing, construction, and the oil and gas industry.

One of the most common uses for petroleum distillates is as a fuel for motor vehicles. Petroleum distillate is used in the production of gasoline and diesel fuel for cars and trucks. In addition to being used as a fuel source for motor vehicles, petroleum distillates can also be used in commercial aircraft engines as jet fuel.

Petroleum distillates are also used in various industrial applications. They are commonly used in the production of asphalt for roads, as well as in paints and solvents. Additionally, petroleum distillates are often added to lubricants to improve their viscosity and reduce friction between moving parts.

Petroleum distillates can also be found in certain consumer products such as detergents and cleaners. Many household cleaners contain petroleum distillate derivatives because they have superior cleaning properties compared to other ingredients. Additionally, some cosmetics such as lip balms contain petroleum distillate derivatives due to their emollient properties which help keep lips soft and moisturized.

Finally, petroleum distillates can be found in many medical products such as antiseptics and ointments due to their antifungal properties which help protect wounds from infection. Petroleum-based ointments are often used on minor cuts or scrapes because they help reduce inflammation while keeping the wound clean and free from bacteria or viruses.

The Benefits of Using Petroleum Distillates

Petroleum distillates are a valuable resource for a variety of industrial and commercial applications. They are used to manufacture many products, including solvents, fuel additives, lubricants, and more. The main benefits of using petroleum distillates are its versatility, cost-effectiveness, and environmental friendliness.

Versatility is one of the most notable advantages of using petroleum distillates. They can be used in a variety of industries and applications due to their wide range of properties. Petroleum distillates can be tailored to meet specific needs, such as viscosity, flash point, and boiling point. This makes them suitable for use in manufacturing processes that require specific qualities.

Another advantage of using petroleum distillates is their cost-effectiveness. Due to their low cost production costs, they are often the preferred choice for industrial applications. Moreover, they provide excellent performance at a fraction of the cost compared to other types of hydrocarbons. As a result, they provide an economical option that helps businesses save money on production costs while ensuring high quality products and services.

Finally, petroleum distillates are also environmentally friendly when compared to other hydrocarbons such as gasoline or diesel fuels. They have a lower carbon footprint than other hydrocarbons since they are made up mostly of carbon dioxide instead of carbon monoxide or nitrogen oxide emissions that would otherwise occur with the combustion process in traditional fuels. Furthermore, petroleum distillates also contain fewer pollutants such as sulfur dioxide which can cause acid rain or ground water pollution when released into the atmosphere from burning traditional fuels like gasoline or diesel fuel.

In conclusion, petroleum distillates offer numerous advantages over traditional hydrocarbon fuels due to its versatility, cost-effectiveness, and environmental friendliness making it an ideal choice for many different industries and applications.

What Are the Risks of Using Petroleum Distillates?

Petroleum distillates are a byproduct of crude oil refining and can be found in many everyday products from lubricants to fuels. However, there are some associated risks related to the use of petroleum distillates. These include exposure to volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs), potential for fire or explosion, and risk of contamination from storage tanks and pipelines.

When petroleum distillates are used or stored improperly, VOCs and HAPs can be released into the air, posing health risks such as irritation to eyes, skin, and lungs; headaches; dizziness; nausea; damage to organs; and cancer. In addition, when handled incorrectly, petroleum distillates may pose a risk of fire or explosion due to their flammable nature.

Finally, improper storage or management of petroleum distillates can lead to contamination of soil and water supplies due to leakage from storage tanks or pipelines. This contamination can have serious consequences for both human health and the environment. For example, contaminated drinking water can cause illness in people who consume it.

Given these risks associated with using petroleum distillates, it is important that they are handled safely and responsibly in order to minimize potential harm. This includes proper containment of the substances within tanks or pipelines when they’re being transported or stored, as well as following best practices for handling them when they’re being used.

Conclusion

Petroleum distillate is a valuable resource that is used in a variety of industries. It can be used for fuel, heating oil, lubricants, and many other products. Petroleum distillate is also the product of crude oil refining and the production of petrochemicals. It has a range of characteristics that make it suitable for different applications, such as its relatively low price and its ability to be easily transported and stored. Its versatility has enabled it to remain an important part of industry in many countries around the world.

While petroleum distillate has many beneficial uses, its potential environmental impacts should not be overlooked. Petroleum distillates are highly flammable and can pollute air, soil, and water if not handled correctly. Additionally, the production process releases harmful emissions into the atmosphere that contribute to global warming. For these reasons, it is important for industry to take steps to reduce the environmental footprint of petroleum distillates while still harnessing their benefits.

In summation, petroleum distillate is an important resource with numerous applications in industry today. Its versatility makes it an attractive option for many industries around the world. However, the environmental impacts of petroleum distillates must be taken into account when considering their use in order to ensure that their benefits are not outweighed by their potential harms to the environment.