Distillation in chemistry is a process of separating components of a mixture through the use of selective boiling and condensation. It is a physical separation technique that occurs when a liquid mixture is heated to its boiling point, so that the vapors produced can be condensed back into liquid form. This process can be used to separate liquids with different boiling points, as well as to purify and concentrate solutions. Distillation is an important tool for chemists in many fields, such as organic chemistry and biochemistry.Distillation is a process of separating the components or substances from a liquid mixture by using selective boiling and condensation. This process involves heating a mixture until the components of the mixture vaporize, then cooling and collecting the resulting vapor which is then condensed back into a liquid. Distillation is used to purify liquids, separate mixtures, and recover solvents from solutions.

Distillation in Chemistry

Distillation is a process used in chemistry to separate components of a mixture by utilizing differences in their boiling points. It is one of the oldest forms of separation technology, with its origins traced back to ancient Egypt and China. Distillation is a process where a liquid mixture is heated until it vaporizes, then condensed back into liquid form. The components of the mixture have different boiling points, so the vaporized material will contain the component with the lower boiling point. This vapor is then condensed and collected as a separate liquid from that of the original mixture.

How Does Distillation Work?

The distillation process begins by heating the liquid mixture until its components vaporize. The vapors are then collected and cooled until they condense back into liquid form. The component with the lowest boiling point will condense first, followed by progressively higher boiling point components as temperatures increase. This allows for component separation based on their different boiling points.

The distillation process occurs over multiple rounds or stages, depending on how many components are present in the original mixture and how much separation is desired. During each round, only

Types of Distillation

Distillation is a process used to separate or purify components from a liquid mixture by selective boiling and condensation. It is an ancient technique, and is still widely used today in many industries. There are various types of distillation processes, each with its own advantages and disadvantages. The most common types of distillation are fractional distillation, steam distillation, vacuum distillation, molecular distillation, short-path distillation, and azeotropic distillation.

Fractional distillation is one of the oldest forms of distillation which involves the use of boiling points to separate components from a mixture. In this type of distillation, the different components in the mixture have different boiling points which can be exploited to separate them from each other. This type of process has been used for centuries to create products such as whiskey and vodka.

Steam distillation is a process in which steam is passed through a mixture at high pressures in order to separate its components. This type of process is most commonly used for essential oils and aromatic compounds as well as food flavoring agents. It is an effective

Advantages of Distillation in Chemistry

Distillation is a process used in chemistry to separate a mixture of liquids with different boiling points. In this process, the liquid mixture is heated to produce vapors, which are then condensed back into a liquid form. Distillation is one of the oldest and most widely used methods of chemical separation and purification. It has many advantages over traditional separation techniques such as filtration and crystallization.

One of the main advantages of distillation is that it can be used to separate components with a wide range of boiling points, from low-boiling point solvents such as water to high-boiling point solvents such as alcohols. This makes distillation an ideal method for separating complex mixtures that would be difficult or impossible to separate by other means. Additionally, distillation can achieve very high levels of purity, since it eliminates impurities by vaporizing them and then condensing them away from the desired product.

Another advantage of distillation is that it is relatively simple and cost-effective compared to other separation techniques. The equipment required for distillation is relatively

Applications of Distillation

Distillation is one of the most widely used processes in many industries for separating various components from a mixture. It is a process in which vaporization and condensation are used to separate a liquid from an impure mixture. Distillation has many applications in various industries such as chemical, pharmaceutical, food, and energy production.

In the chemical industry, distillation is used to separate and purify different types of chemicals from a mixture. It is also used to separate crude oil into different fractions that can be further processed into usable products such as gasoline, diesel, kerosene, and lubricating oils. Distillation also finds application in the pharmaceutical industry for the production of medicines and drugs.

In the food industry, distillation is used for producing alcoholic beverages such as beer, wine, and whiskey. It is also used to separate essential oils from plant materials which are then further processed for use in food products such as flavorings and fragrances. Distillation also finds application in energy production where it is used to produce biofuels such as ethanol and biodiesel from biomass materials such as vegetable

Distilling Chemicals

Distilling chemicals is the process by which a mixture of compounds is heated and cooled in order to separate the components. The distillation process is used to purify a variety of chemicals, ranging from crude oil and fuel products to pharmaceuticals and perfumes. However, this process also comes with a number of challenges.

One major challenge with distilling chemicals is the fact that some components are more volatile than others. This means that when they are heated, different compounds will boil off at different temperatures. As a result, the distillation process must be carefully monitored in order to ensure that all components are collected at their respective boiling points.

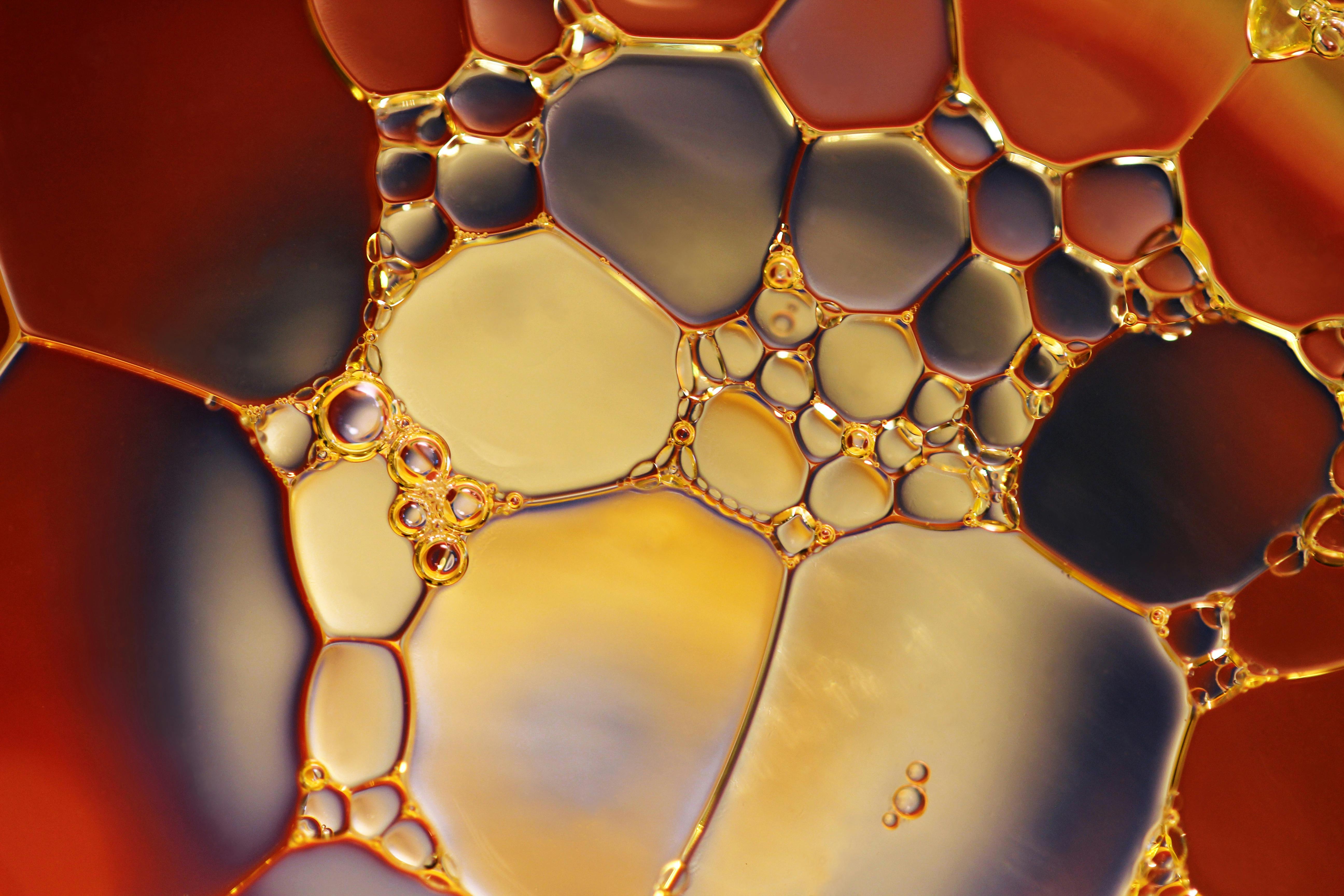

Another challenge with distilling chemicals is the fact that some compounds can form emulsions when they come into contact with water or other liquids during the heating and cooling process. These emulsions can make it difficult for components to separate properly, resulting in an impure product. This problem can be mitigated by carefully controlling the temperature during the distillation process and ensuring that only pure chemicals are used.

Finally, some

Pressure

The pressure of the system has a significant impact on the efficiency of a chemical distillation process. By altering the pressure, the boiling point of the molecules changes, which affects how easily they evaporate and condense. A lower pressure allows for easier evaporation and condensation, while a higher pressure can make it more difficult for molecules to evaporate and condense. This can lead to less efficient distillation.

Temperature

Temperature is another factor that affects the efficiency of a chemical distillation process. The temperature influences how quickly molecules evaporate and condense. A higher temperature causes faster evaporation and condensation, while a lower temperature slows down these processes. If the temperature is too high or low, it can lead to an inefficient distillation process.

Type of Molecules

The type of molecules being distilled also has an effect on the efficiency of a chemical distillation process. Different types of molecules have different boiling points and vapor pressures, which affect how easily they evaporate and condense. Some molecules may be more difficult to

General Safety

When working with the chemical distillation process, it is important to observe general safety protocols. This includes wearing the appropriate personal protection equipment (PPE), such as gloves, goggles, and a face shield. Ensure that ventilation systems are in place to help reduce the risk of inhalation of harmful chemicals. Make sure that all areas of the laboratory are free from any combustible materials. Be aware of any potential hazards and take appropriate measures to protect yourself and those around you.

Equipment Safety

Ensure that all equipment used in the distillation process is properly maintained and inspected on a regular basis for any signs of wear or damage. If any safety issues arise, they should be addressed immediately. Make sure that all connections are secure and protective shields are in place to prevent potential spills or leaks. Check for any gas leaks or electrical hazards before starting up the equipment.

Chemical Safety

Always wear protective clothing when handling chemicals during the distillation process. Be aware of what chemicals are being used in order to understand their potential hazards and how to properly

Conclusion

Distillation is an important part of chemistry as it is used to purify and separate different compounds. This process involves the boiling of a liquid mixture, and then the condensation of the vapors produced. Distillation is one of the oldest forms of chemical separation and can be used to separate liquids from solids, or to separate components from a mixture. It is also used to create high-purity liquids for use in laboratories. By understanding how distillation works, chemists can better understand the fundamental principles of chemistry and improve their ability to work with various compounds.

Overall, distillation plays a key role in chemistry by providing chemists with a method for separating and purifying compounds. With its ability to produce high-purity liquids, distillation allows chemists to more accurately study and analyze complex mixtures of compounds. By understanding how this process works, chemists can continue to develop new tools that will help them further their research into the world of chemistry.