Distilling your own peach brandy can be an enjoyable experience. Not only will you get to enjoy the process of making your own spirit, but you will also get to enjoy the end product. With some basic distillation equipment, it is possible to make a high-quality peach brandy at home. In this guide, we’ll take you through all the steps required to turn fresh peaches into a delicious homemade brandy. By the end of it, you’ll be able to confidently create your own unique peach brandy and enjoy sipping it with friends.To distill peach brandy, you will need peaches, yeast, sugar, water, a still (or column distillation apparatus), thermometer, and a hydrometer. You will also need a fermentation container and an airlock to store your fermented mixture. Additionally, you will need bottles or jars to store your finished product in.

Preparing the Fruit for Distillation

The process of preparing fruit for distillation is an important step in the production of quality spirits. Before any type of distillation can take place, the fruit must be prepared correctly to ensure a successful outcome. This involves selecting the right fruits, properly cleaning and cutting them, and then macerating or mashing them into a pulp or juice that can be used in the distillation process.

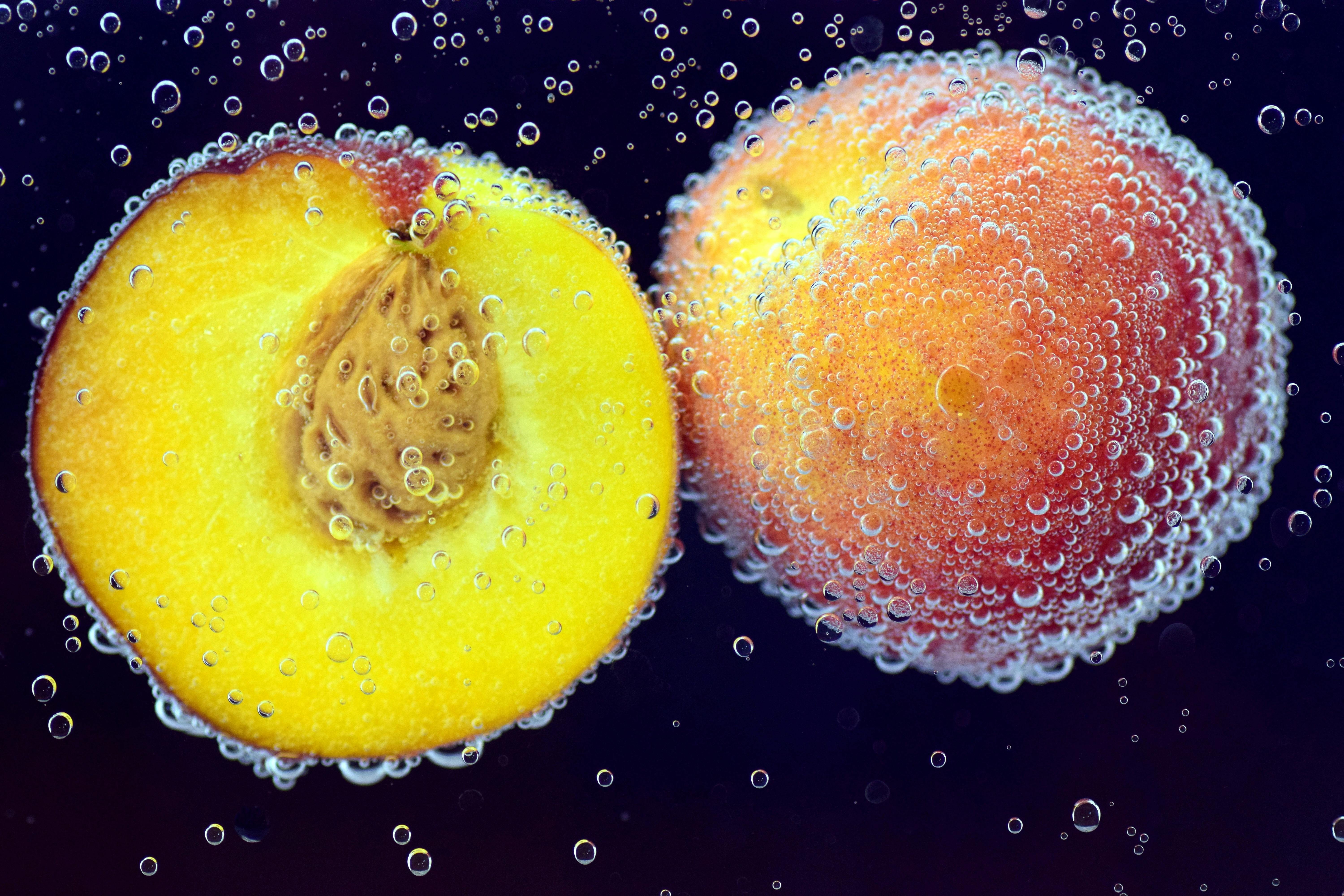

The first step in preparing the fruit is to select suitable fruits. For best results, it is important to choose ripe and healthy fruits that are free from disease or pests. This ensures that only the best ingredients are used in producing quality spirits. Once suitable fruits have been selected, they should be thoroughly washed and peeled to remove any dirt, bacteria, and other contaminants that could negatively affect the taste of the finished product.

After washing and peeling, it is time to cut up the fruit into small pieces so that it can be mashed or macerated. Depending on what type of spirit is being produced, different techniques will be used to break down the fruit pulp or juice into a form that can easily be distilled. For example, when making

Choosing Your Equipment for Distilling Peach Brandy

Distilling peach brandy requires the proper equipment to ensure that you get the best possible results. The most important piece of equipment is the still, as it is responsible for converting the alcohol from the peach juice into brandy. You will need to choose a still that is appropriate for the amount of brandy you wish to produce. Additionally, you will need to choose other pieces of equipment such as fermentation tanks, a mash tun, and distillation columns.

When selecting a still, you should consider both its size and its construction materials. A smaller still can be easier to manage and maintain, although it may not be able to produce as much brandy as a larger one. On the other hand, larger stills are more expensive but can produce larger quantities of brandy. In terms of materials, copper is often considered the best option for distillation due to its heat-conducting properties and durability.

In addition to the still itself, there are other pieces of equipment that are necessary for making peach brandy. These include fermentation tanks which are used to ferment

Sanitizing Your Equipment

Keeping your equipment clean and sanitized is an important part of any fitness program. Regular cleaning and sanitizing will help reduce the spread of germs and bacteria and ensure that your equipment is safe to use. Here are some tips for sanitizing your fitness equipment:

Start by wiping down your equipment with a disinfectant wipe or spray. Make sure to cover all surfaces, including benches, machines, mats, and other items that you may touch during exercise. Wipe or spray each item until it is completely dry to ensure all germs have been eliminated.

If possible, take the time to deep clean your equipment at least once a month. Use a mild detergent with warm water and scrub each piece of equipment thoroughly before rinsing it off with clean water. Allow the items to air dry completely before putting them away or using them again.

Be sure to check the manufacturer’s instructions for any special cleaning instructions for your particular type of fitness equipment. Depending on the material, some pieces may require specific cleaning products or techniques in order to keep

Fermenting the Peach Mash

Fermenting the peach mash is an important step in making peach wine. It is a process that requires patience, as it can take several weeks for the fermentation to be completed. The first step in the fermentation process is to create a mash from the peaches. This can be done by mashing or crushing the fruit and then straining out any solids. Once this is done, you will need to add yeast to the mash and allow it to ferment. During this process, the yeast will convert sugar into alcohol and carbon dioxide.

Once fermentation has begun, it is important to monitor the temperature of the mash closely. The ideal temperature range for fermentation is between 18-21 degrees Celsius (64-70 degrees Fahrenheit). If temperatures drop too low, fermentation may slow or even stop altogether. In addition, temperatures that are too high can cause spoilage and off flavors in your wine.

It is also important to check the progress of your fermentation regularly by taking regular gravity readings with a hydrometer or refractometer. These readings will tell you how much sugar has been converted into alcohol during fermentation and when it has finished ferment

Heating the Fermented Mash

The fermented mash is heated to a specific temperature for a specific length of time, depending on the type of whiskey being produced. This step is known as “distillation” and is done in a large copper still. The still can produce either low wines or high wines, depending on the temperature at which it is heated. Low wines are heated to lower temperatures, while high wines are heated to higher temperatures. During this process, the alcohol evaporates and is captured in a separate container. The alcohol-rich vapor is then cooled down and condensed back into liquid form, which is then ready for aging. This process gives whiskey its distinct flavor and aroma.

The next step in making whiskey is aging. Depending on the type of whiskey being made, it can be aged anywhere from several months to several years. During this time, the whiskey sits in oak barrels that previously held other spirits such as bourbon or sherry. This helps give the whiskey its distinct flavor profile and color. After aging, some whiskeys may be blended with other spirits or flavored with natural ingredients such as fruit or spices before being bottled and sold.

Collecting the Condensed Alcoholic Vapor and Cooling it Down

Distilling alcoholic beverages requires collecting the condensed vapor after it has been heated. This vapor contains the ethanol which is responsible for the alcoholic content of the beverage. It is important to cool down this vapor so that it condenses back into liquid form, in order to be collected and used in the distillation process.

The most common way to cool down this vapor is by using an apparatus called a condenser. This condenser works by cooling down the hot gas or vapor which has been produced during distillation, so that it can be collected in a container such as a flask or bottle. The condenser works by running cold water through a coil of tubing, which absorbs the heat from the hot gas or vapor. As this hot gas or vapor passes through the coil of tubing, it cools down and eventually condenses back into liquid form.

Once cooled and condensed, this liquid can then be collected and used in the distillation process. This liquid contains all of the ethanol which was present in the original beverage, as well as other volatile compounds which contribute to its flavor

Testing the Alcohol Content of the Brandy

Testing the alcohol content of brandy is an important part of the distillation process. This is done to ensure that the brandy contains a safe level of alcohol and has a balanced flavor. The most common method for testing alcohol content is by using a special hydrometer, which measures the density of a liquid. The density of alcohol will be higher than that of water, so it can be used to estimate the percentage of alcohol in the brandy.

The process begins by measuring out an appropriate amount of brandy into a flask or other suitable container. The hydrometer is then placed into the flask and allowed to settle for several minutes before being removed and read. The hydrometer should be kept clean at all times, as any dirt or debris can affect its accuracy. Once read, the hydrometer should indicate the amount of alcohol present in the brandy sample.

Another way to test for alcohol content is by using an electronic device known as an abv meter. This device measures both temperature and specific gravity, which can then be used to calculate an approximate

Conclusion

Distilling peach brandy is a rewarding and enjoyable process that yields a high-quality product. With the right ingredients, equipment, and method, you can easily produce your own delicious spirit. The fermentation process should be carefully managed to ensure optimal yeast activity, while the distillation process requires skill and attention to detail in order to produce the best possible result. With a little practice and patience, you can make a peach brandy that will be enjoyed by family and friends for years to come.

Making your own brandy is an art form that requires time and dedication. To get the most out of your effort, it is important to take proper care of your equipment and ingredients throughout the entire process. If done correctly, distilling peach brandy can be a rewarding experience that yields a tasty spirit with unique characteristics that cannot be found elsewhere.