Fractional distillation is a process that is used to separate mixtures of different liquids. It involves the use of glass beads which are used to increase the surface area of the mixture, allowing for greater contact with the heated surface and thus a more efficient separation of the components. The glass beads also act as a heat exchanger, ensuring that the heat is evenly distributed throughout the mixture. By carefully controlling the temperature, fractional distillation can be used to obtain pure samples of liquids that were previously mixed together.Glass beads are used in fractional distillation as a support for the condensation of vapor and to create additional surface area for the vapor to condense on. This allows for a more efficient distillation process by increasing the surface area that the vapor can interact with, resulting in a more effective separation of compounds.

What Is The Purpose of Glass Beads In Fractional Distillation?

Glass beads are used in fractional distillation to increase the surface area of the distilling flask. By increasing the surface area, more molecules can be exposed to the heat of the distillation process, allowing for a more efficient separation. Additionally, glass beads provide nucleation sites which help to break up large molecules and reduce clumping or sticking to the walls of the flask. This helps to ensure an even distribution of heat and a more efficient separation process. Glass beads also help to collect condensate that forms during the distillation process, which further enhances efficiency. Finally, glass beads can also be used as packing material for packed columns in fractional distillation setups. This provides greater control over reflux and further enhances separation efficiency.

How Do Glass Beads Work In Fractional Distillation?

Fractional distillation is a technique used to separate mixtures of liquids with different boiling points. Glass beads are commonly used in this process, as they help increase the surface area of the liquid and allow for better heat transfer. This helps to speed up the distillation process and increase the efficiency of separation. The glass beads also act as a barrier between the two liquids, preventing them from mixing with each other. As a result, the distilled product is purer and more concentrated than it would be without using glass beads.

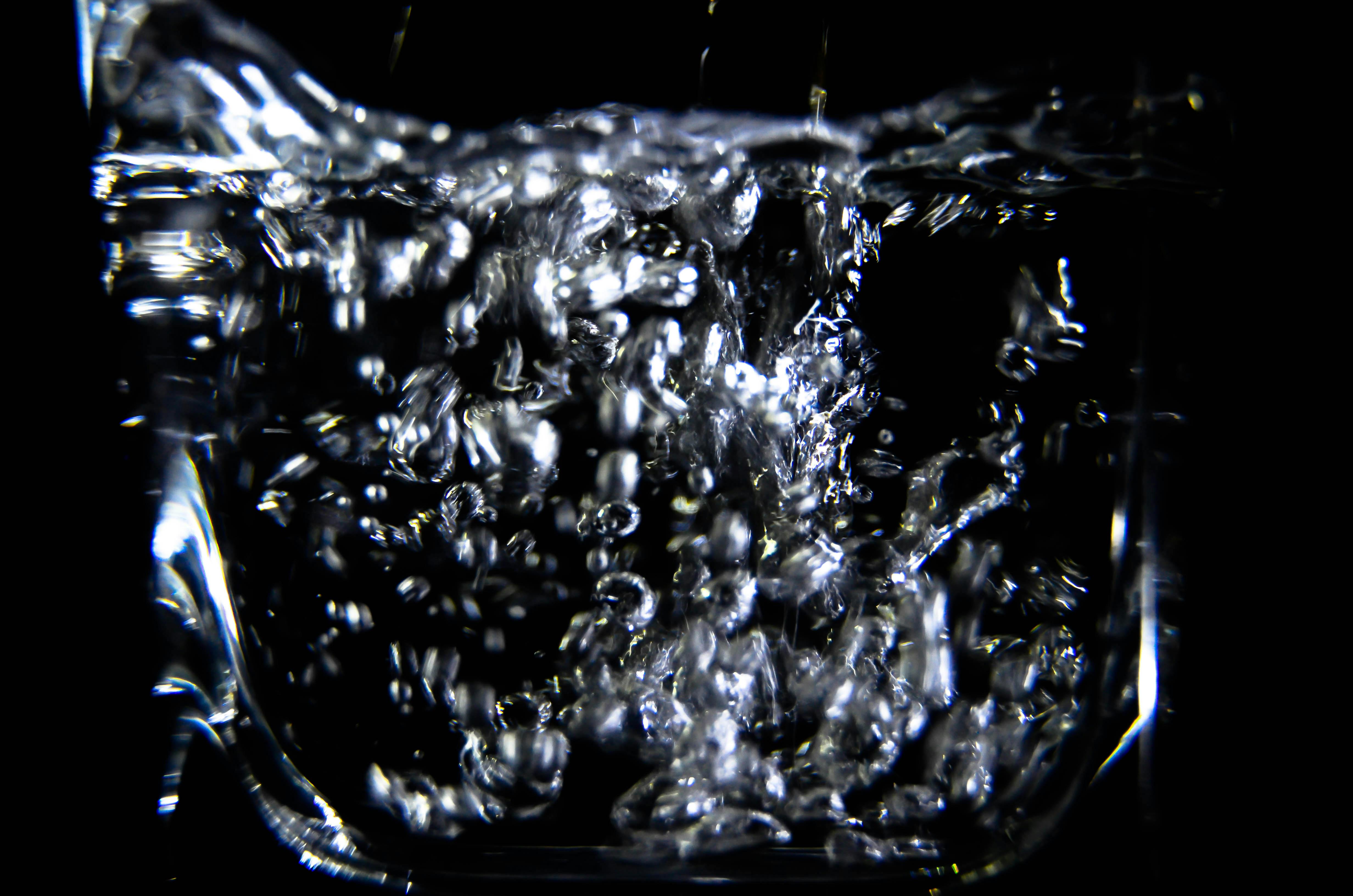

The glass beads are typically placed in a fractionating column, which is then filled with the mixture of liquids to be distilled. Heat is applied to one end of the column, causing some of the liquid mixture to evaporate and rise up through it. As it rises, it meets cooler temperatures along its way and condenses back into liquid form at various points in the column. The condensed liquid then drops down onto glass beads where it is quickly cooled down, allowing for a more complete separation between different components in the mix.

The size and shape of the glass

The Benefits of Using Glass Beads in Fractional Distillation

Fractional distillation is a process used to separate components of a mixture into different fractions. It is an important technique used in the petrochemical, pharmaceutical, and chemical industries. While there are several types of fractional distillation techniques, using glass beads in this process provides several benefits.

Glass beads are an ideal material for fractional distillation as they have good heat transfer properties and can withstand high temperatures. This makes them suitable for use in a variety of applications. Additionally, glass beads are non-reactive and do not corrode or react with the chemicals being distilled. This ensures that the quality of the final product remains intact throughout the distillation process.

Another benefit of using glass beads is that they help increase the efficiency of fractional distillation by creating more surface area for distillate to move across. This allows for faster separation of components and increases overall efficiency. Additionally, glass beads provide a more even heat distribution throughout the system, which helps to reduce any potential distortions or uneven fractions in the final product.

<

Advantages of Using Glass Beads In Fractional Distillation

Fractional distillation is a process used to separate mixtures of liquids with different boiling points. This process involves the use of glass beads, which act as a support for the fractionating column. Glass beads offer several advantages when used in fractional distillation.

One advantage is that glass beads provide a large surface area for vaporization and condensation to take place. This increases the rate of separation and makes the process more efficient, as more vapor can travel through the column at any given time. Additionally, glass beads are inert and chemically stable, so they will not react with any of the materials in the mixture, allowing for accurate and consistent results.

Another advantage is that glass beads are highly resistant to thermal shock, meaning they can withstand sudden changes in temperature without fracturing or breaking. This makes them ideal for use in fractional distillation, as temperatures can quickly rise and fall during the process. Furthermore, glass beads are also relatively inexpensive compared to other materials typically used in fractional distillation columns.

Lastly

How To Choose The Right Type of Glass Beads For Fractional Distillation

Fractional distillation is a process used to separate components of a liquid mixture that have different boiling points. This process involves heating the liquid mixture to its boiling point, and then passing steam through glass beads to separate the components. Choosing the right type of glass beads for fractional distillation is an important step in this process, as it can affect the efficiency and quality of the separation.

The size and shape of the glass beads will affect how much heat is absorbed by each bead, which can have an impact on the efficiency of the fractional distillation. The surface area of each bead will determine how much steam is able to pass through them, which affects how quickly each component can be separated. The shape of the beads will also affect how quickly they are heated and cooled, which affects how long it takes for each component to be separated.

The type of glass used for the beads will also affect their performance in fractional distillation. Different types of glass have different properties that can affect their ability to absorb heat and

Using the Right Amount of Glass Beads For Fractional Distillation

Fractional distillation is a process used for separating mixtures of liquids into fractions based on their boiling points. The process relies on the principle that different compounds have different boiling points and can be separated by fractional distillation. To maximize the efficiency of the fractional distillation process, it is important to use the right amount of glass beads as packing material.

Glass beads are placed in a fractionating column as packing material to provide a large surface area for vapor bubbles to condense on. This helps increase the efficiency of heat exchange and facilitates better separation of different fractions. If too few glass beads are used, then there is not enough surface area for heat exchange, resulting in inefficient fractional distillation. On the other hand, if too many glass beads are used, then the column becomes too packed and does not allow enough vapor bubbles to pass through, also resulting in inefficient fractional distillation.

In order to ensure efficient fractional distillation, it is important to use the right amount of glass beads for packing material. Generally speaking

Incorporating Glass Beads into Fractional Distillation

Fractional distillation is an important process used in many industries to separate mixtures of liquids. This type of distillation can be used to create very pure products or separate mixtures that cannot be done using other techniques. Incorporating glass beads into fractional distillation can help to improve the efficiency and accuracy of the process.

Glass beads are usually placed in a fractional distillation column, which is then heated to separate the components of the mixture. The beads act as a catalyst, allowing different compounds to vaporize at different temperatures and speeds. This can help to improve the separation of components, resulting in a more pure product with fewer impurities. The use of glass beads also helps to reduce the amount of energy required for the separation process.

Glass beads also help reduce foaming and bubbling that can occur during fractional distillation. Foaming and bubbling can lead to inaccurate results, so reducing them is essential for effective fractional distillation. Glass beads act as nucleation sites for bubbles, reducing their formation and allowing more effective separation.

Conclusion

Glass beads in fractional distillation act as support to the packing materials which prevent the liquid from overflowing and help in the efficient separation of two or more liquids of different boiling points. They also help to increase the surface area of contact between vapor and liquid, thus increasing the rate of condensation and distillation. Additionally, they are also used to reduce the velocity of vapor, thus allowing for more efficient heat transfer. The use of glass beads in fractional distillation is an important step in achieving good product quality and purity.

In conclusion, glass beads are essential for fractional distillation as they provide stability and are key for efficient heat transfer. They also help to prevent overflow of liquids during the process and increase surface area contact between vapor and liquid. It is therefore clear that glass beads play an important role in fractional distillation, making it a key method for purifying liquids.