Distillation is an important process used in many industries to separate, purify, and concentrate materials. It is a process of heating a liquid mixture to separate it into its component parts based on their different boiling points. It is widely used in industries such as food and beverage, pharmaceuticals, petrochemicals, and chemical manufacturing. Distillation has many advantages over other separation techniques such as filtration or centrifugation because it can be used to separate components with very similar boiling points and can also be used on volatile liquids. In addition, it is cost effective, efficient, and relatively easy to operate.Distillation is a process used in industrial applications to separate or purify liquids based on their different boiling points. It is a physical process that involves heating a mixture of substances and condensing its vapors to form two or more distinct liquids. Distillation is widely used in the chemical industry for the separation of mixtures, production of alcohol, production of essential oils and fragrances, and desalination of seawater.

Types of Distillation Used in Industry

Distillation is a process of separating components from a mixture based on their different boiling points. It is one of the most widely used methods for separating mixtures and is used throughout many industries. The different types of distillation used in industry include simple distillation, fractional distillation, steam distillation, vacuum distillation and azeotropic distillation.

Simple distillation is a process used to separate two liquids that have different boiling points. It involves heating the mixture until it boils and then collecting the vapours that are produced. The vapours can then be condensed into two separate liquid fractions. This method is commonly used to separate water from ethanol or other organic compounds.

Fractional distillation is similar to simple distillation but involves more steps and yields more precise results. This method begins with heating the mixture until it boils and then passing the resulting vapours through a fractionating column which contains several trays or plates. As the vapours pass through each tray they condense and fall back into the pot below, creating several distinct liquid fractions at various temperatures. This method can

Benefits of Distillation in Industry

Distillation is an important process used in many industries, including the food and beverage, pharmaceutical, and oil and gas industries. It is a separation process that involves the boiling of a liquid mixture to separate its components. The vaporized components are then condensed and collected. Distillation can be used to purify liquids, separate mixtures of liquids with different compositions, or create a desired product from a given mixture. The benefits of distillation in industry include:

The first benefit is cost-effectiveness. Distillation is much less expensive than other separation processes such as chromatography or fractional distillation. This makes it an attractive option for many industries that need to separate components from a given mixture but are unable to invest in more expensive equipment.

Another benefit is safety. Distillation is typically performed at a lower temperature than other separation methods and does not require the use of hazardous chemicals or solvents. This makes it much safer than other methods, especially when dealing with volatile or toxic materials.

Distillation also offers high selectivity, meaning that it can be used to

Challenges of Distillation in Industry

Distillation is an important process for the production of many industrial products, ranging from fuels and solvents to perfumes and food ingredients. It is also used to purify water, separate waste streams, and recycle valuable components from raw materials. Despite its widespread use in industry, distillation can be a difficult process to control due to its sensitivity to changes in temperature, pressure, and composition of the feedstock. In addition, the complexity of the technology makes it difficult to troubleshoot and optimize when unexpected problems arise.

The first challenge with distillation is maintaining consistent conditions throughout the process. Any changes in temperature or pressure can cause variations in product quality and yield. This can lead to costly waste if not properly managed. It is also important to monitor the feedstock closely for any contaminants that might affect the distillation process or product quality.

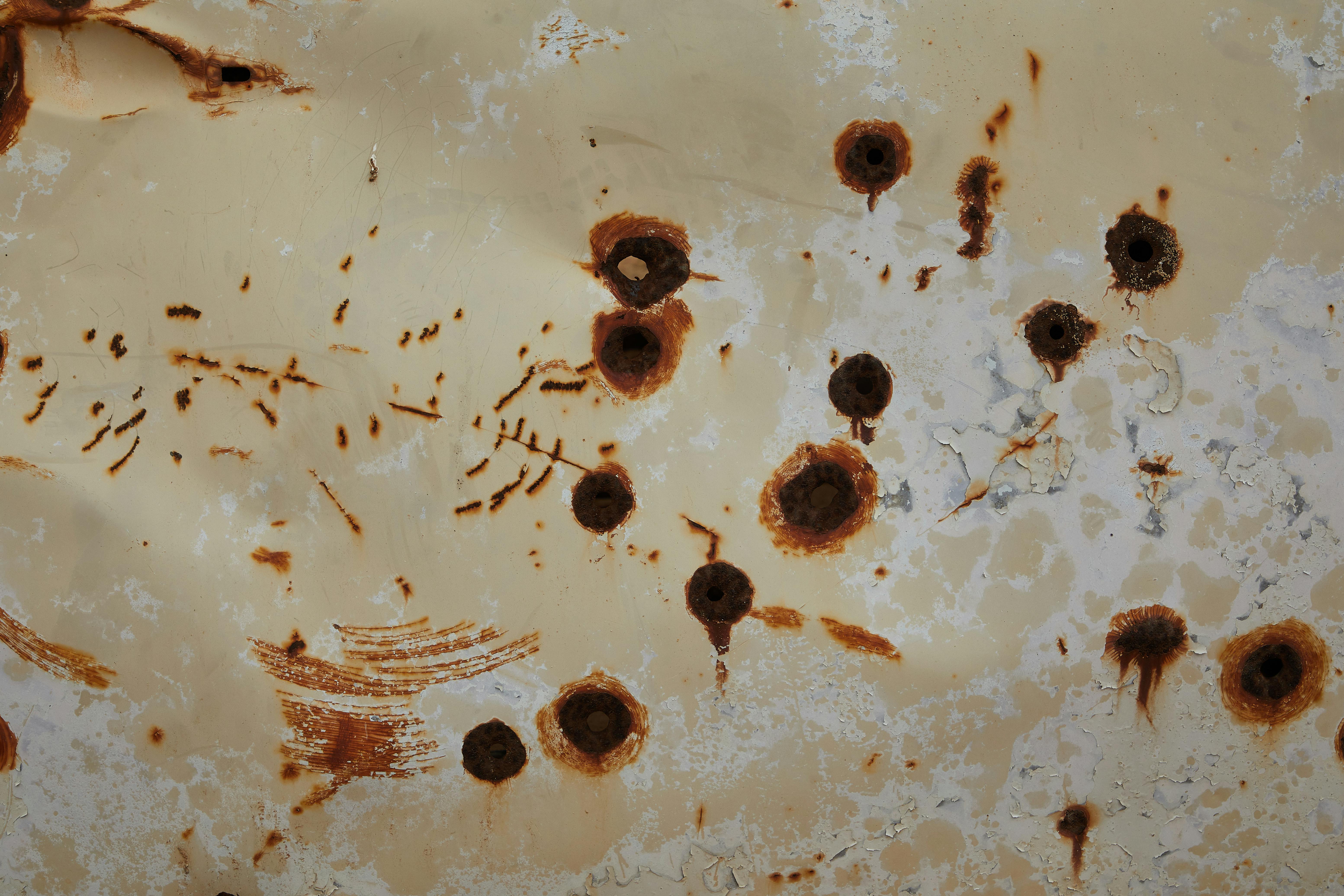

Another challenge with industrial distillation is ensuring efficient operation of the equipment. If not managed correctly, poor efficiency can lead to increased energy use and higher operational costs. In addition, fouling or corrosion of equipment can reduce efficiency even further and require frequent

The Process of Distillation in Industry

Distillation is one of the most commonly used industrial processes for the separation of a mixture of liquids. It is a physical process that involves the heating and cooling of substances in order to separate the components of a liquid mixture. In industry, distillation is used in many different applications and can be used to produce a variety of products, such as fuel, clean water, and medical compounds.

The distillation process is based on the different boiling points of the components in a mixture. When a liquid is heated, its components with lower boiling points will evaporate first, while those with higher boiling points remain in the liquid form. This allows for their separation into two or more streams; one containing only the evaporated components and another containing only those that did not vaporize.

In industrial applications, distillation is commonly carried out in large-scale units known as stills. These are usually fitted with columns filled with packing material through which an incoming hot vapor stream flows. As it passes through these columns, the vapor cools and condenses back into liquid form due to contact with colder surfaces inside the column. This cooling process also causes different

Automation of Distillation in Industry

Distillation is a critical process in the industrial sector, which requires precise control and accurate monitoring in order to ensure efficient operation. Automation of distillation has become increasingly popular in recent years, as it offers greater control and accuracy over the process. Automated distillation can provide more consistent results, reduce energy consumption and improve safety. It also allows for more efficient management of resources and can be used to optimize the production process.

Automated distillation systems use state-of-the-art instrumentation and software to monitor the process, allowing for greater control over the parameters such as temperature, pressure, flow rate and composition. This enables operators to make timely adjustments to ensure efficient operation, reducing energy consumption and improving product quality. Automated systems can also help detect potential problems before they become an issue, allowing for faster problem resolution and reduced downtime.

In addition to improved efficiency, automated distillation systems offer improved safety due to their ability to detect potential hazards and shut down operations if necessary. This is particularly important in hazardous environments where flammable or explosive materials are handled. Automated systems also provide better traceability of production processes which helps ensure

Cost Considerations for Distillation in Industry

Distillation is a process used to separate a mixture of liquids into its component parts, or fractions, based on the different boiling points of each component. Distillation is a common process in many industries such as oil refineries, chemical plants, and food and beverage production. Although distillation is an effective way to separate components, it also requires significant capital investment and operational costs. Companies must consider these costs when deciding whether distillation is the most cost-effective option for their particular process.

The cost of distillation equipment can vary widely depending on the size, type, and complexity of the system needed. Smaller systems may be relatively inexpensive compared to larger systems with more complex designs. Companies must also factor in installation costs for setting up the equipment and connecting it to existing piping networks.

Operational costs for running a distillation system include energy consumption, labor costs, maintenance costs, and raw material costs. Energy consumption can vary depending on the type of system; some systems are more energy efficient than others. Labor costs may include wages for operators as well as other personnel who monitor and maintain the system. Maintenance costs can be high if

Safety and Regulations for Distillation in Industry

Distillation is a process used to separate mixtures of liquids based on their different boiling points. It is an important industrial process that is used in the production of many consumer goods, including fuel, alcohol, and perfumes. As with any industrial process, there are certain safety considerations and regulations that must be followed when using distillation. To ensure the safety of workers and the environment, it is important to understand these regulations and follow them carefully.

The first safety regulation for distillation in industry is to use proper personal protective equipment (PPE). This includes goggles, gloves, respirators, coveralls, and other protective clothing as necessary. The use of PPE helps to reduce the risk of exposure to hazardous chemicals or vapors from the process. Additionally, it is important to ensure that there are no open flames or other sources of ignition near the distillation equipment. This can help to prevent explosions or fires caused by volatile chemicals being released into the atmosphere.

Another important safety regulation for distillation in industry is proper ventilation. Distillation processes may produce noxious gases or vapors which can

Conclusion

Distillation is an incredibly useful process in the industrial sector, providing an efficient and reliable way to separate components of a mixture. It has countless applications, from the production of ethanol to the manufacture of medicines and even food items. Distillation can be used to reduce impurities, increase safety, and produce higher-quality products. It can also be used to purify water or other substances for industrial or commercial use. By combining distillation with other processes such as filtration or precipitation, it is possible to achieve further levels of purity.

Despite its many advantages, distillation is not without its drawbacks. Its cost can be prohibitively expensive for many businesses, and it can require a large amount of energy when compared to other methods of separation. Additionally, distillation can take a long time to complete depending on the type and size of distillation system employed. Nonetheless, there are few processes that offer the same level of efficiency and effectiveness as distillation does for separating compounds from mixtures in industry.